Last time I wrote about tearing apart the camera. A couple days ago we finished putting it back together after making some small tweaks. Instead of writing a bunch of text, let me just show you with pictures. Many of these pictures were taken by Amy Bender, a post-doc on the project (and once a graduate student in Nils Halverson's group in Boulder just like me.) Captions ending with AB denote pictures she took. Thanks for sharing, Amy!

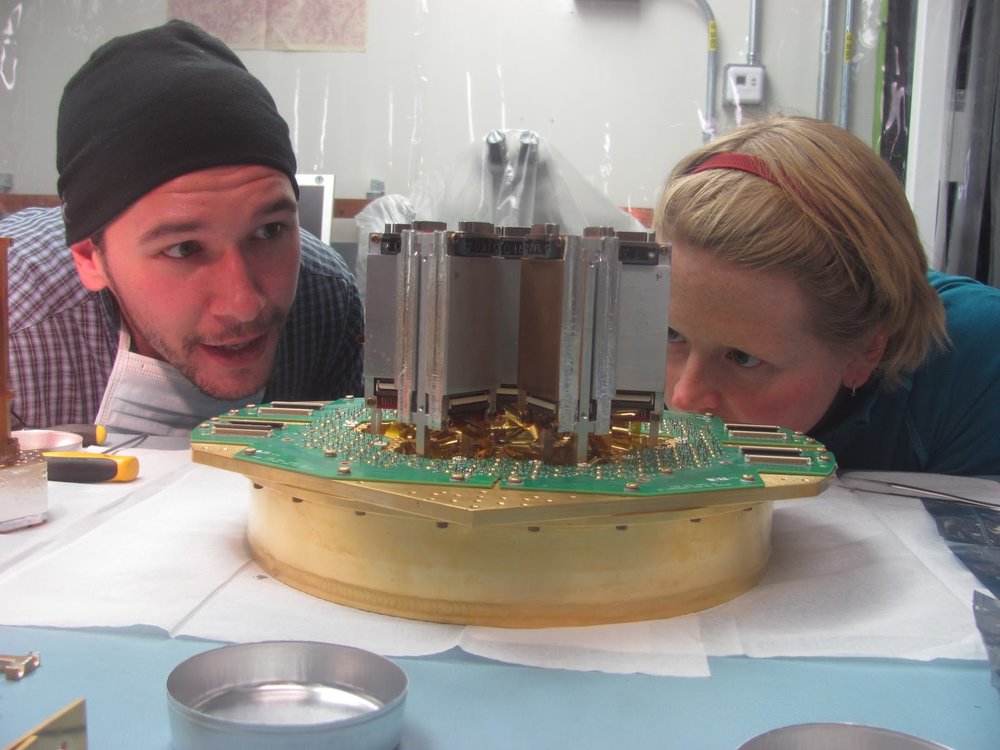

Liz and me inspecting the 150 GHz modules when we tore the camera apart. (Credit: AB)

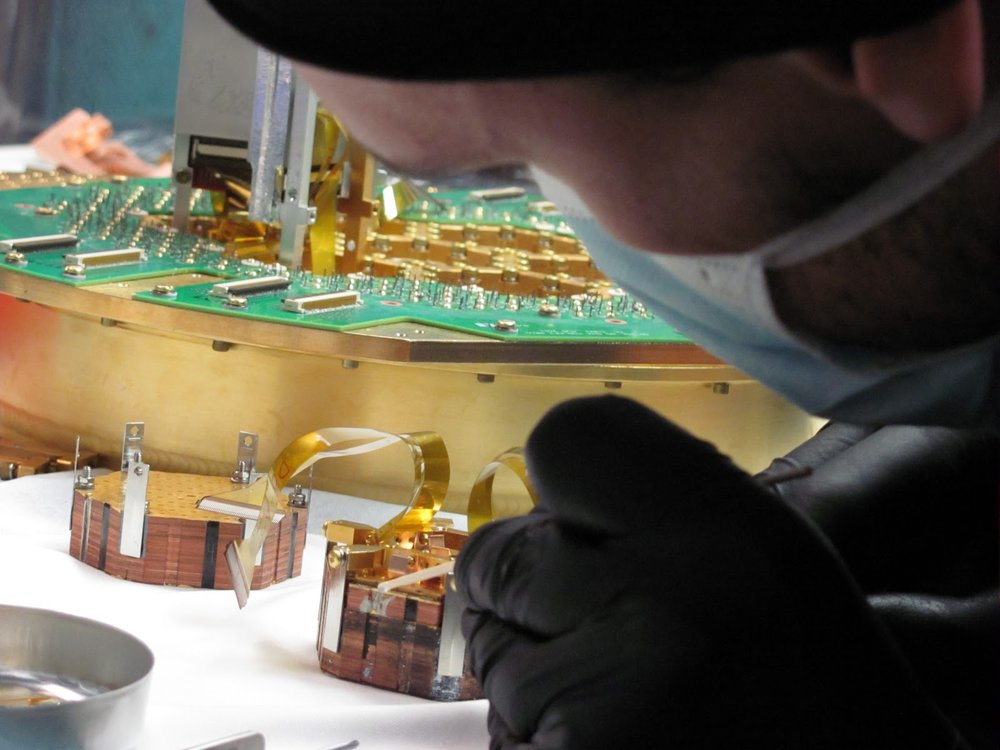

Tiny wire bonds connect the detectors on the new detector wafer to flexible readout cables. The cables are taped down so that I can inspect all the bonds before and after wafer transfer. (Credit: AB)

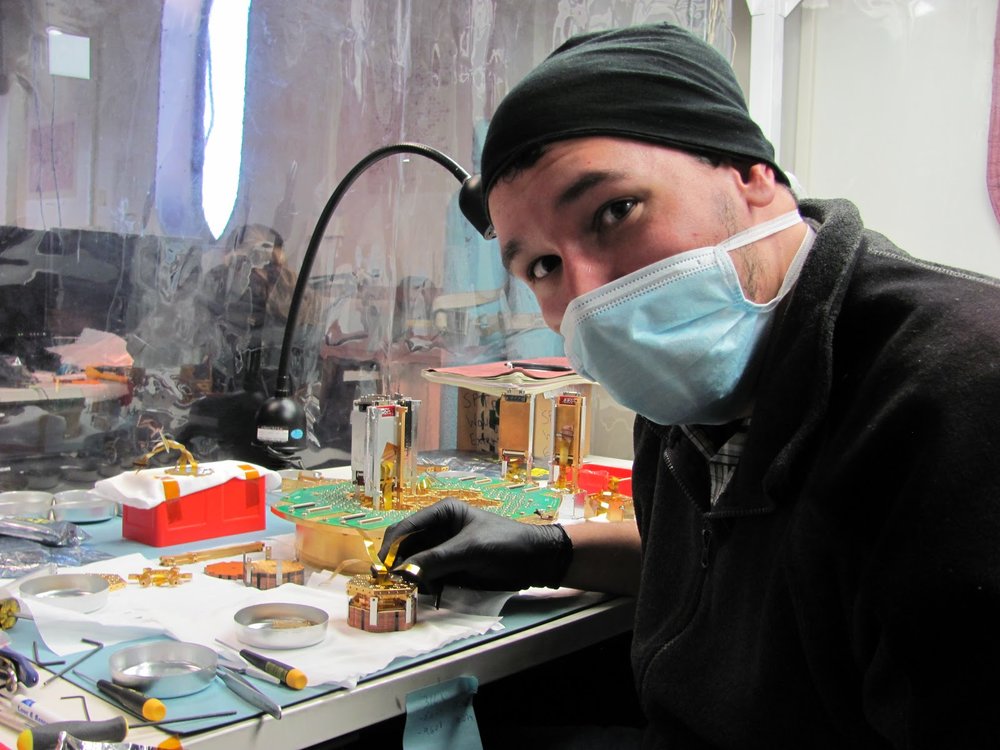

Me preparing a detector wafer sandwich for transfer onto a different horn array. (Credit: AB)

Me assembling a 150 GHz module after installing a new detector wafer. (Credit: AB)

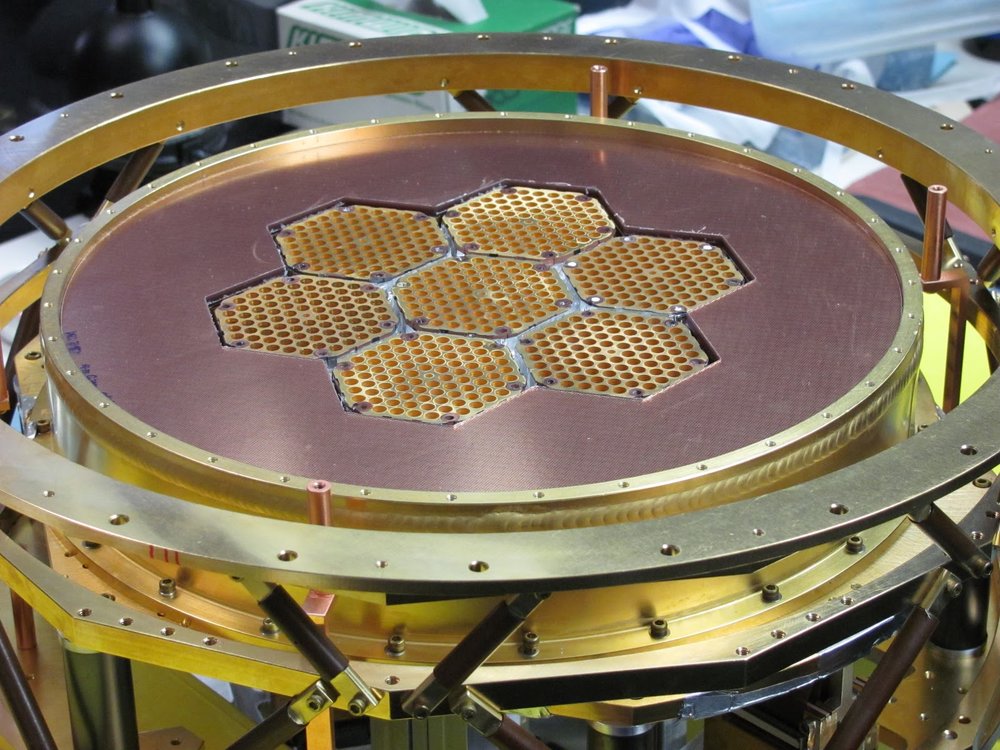

Successfully installed the new detector wafer. Phew! Now I just have to cover up those delicate wire bonds. (Credit: AB)

A close-up shot of the feedhorns in the 150 GHz modules. (Credit: AB)

The Receiver Team with the SPTpol camera before putting on the RF mylar and light filters. (Credit: AB)

The 90 GHz band-defining filter covers the 90 GHz horns, leaving just the 150 GHz module horns visible. Two more band-defining filters finish off the stack. (Credit: AB)

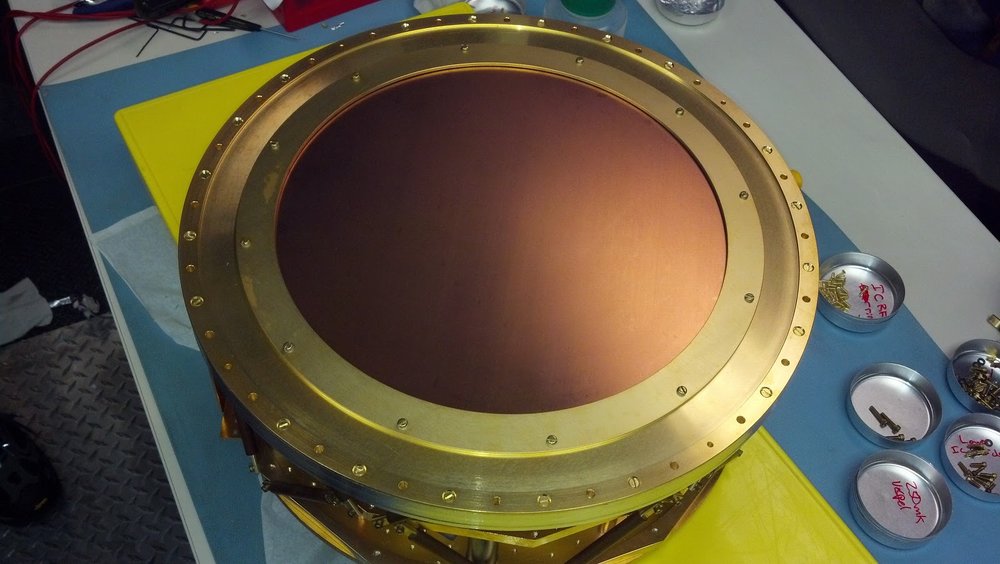

Installing the aluminized mylar RF shielding. (Credit: AB)

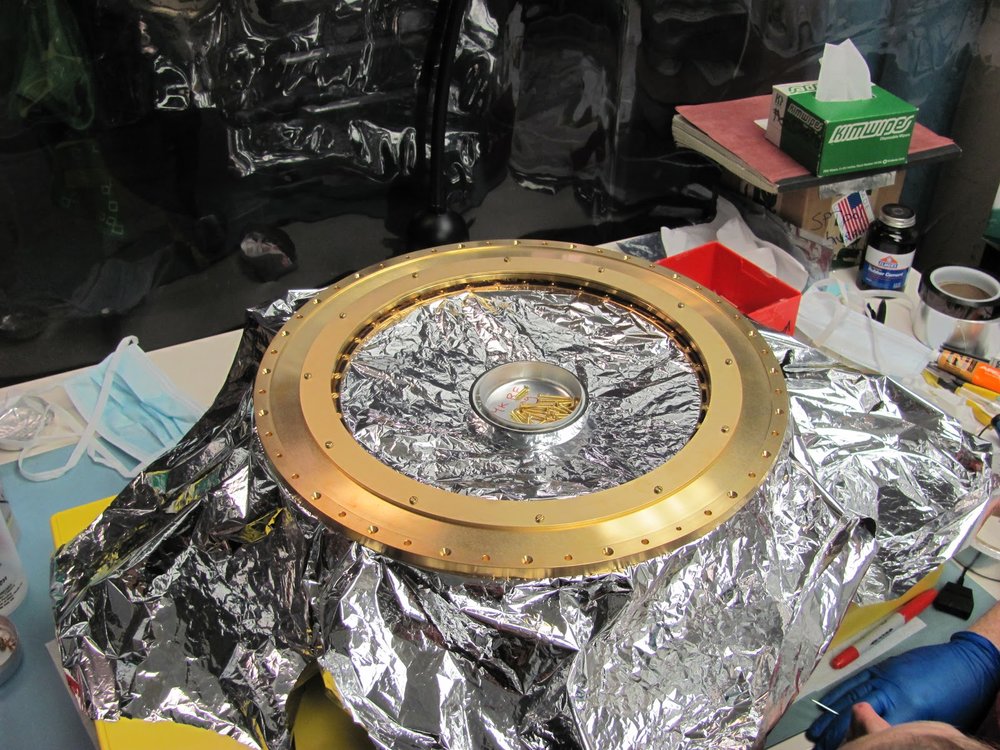

We moved the fourth and last filter directly installed on the camera to sit at a warmer temperature stage compared to last year. It now covers the aluminized mylar RF shielding, which usually looks really cool. But this looks pretty sweet, too.

I carried the camera down the stairs without dropping it! I am relieved. (Credit: AB)

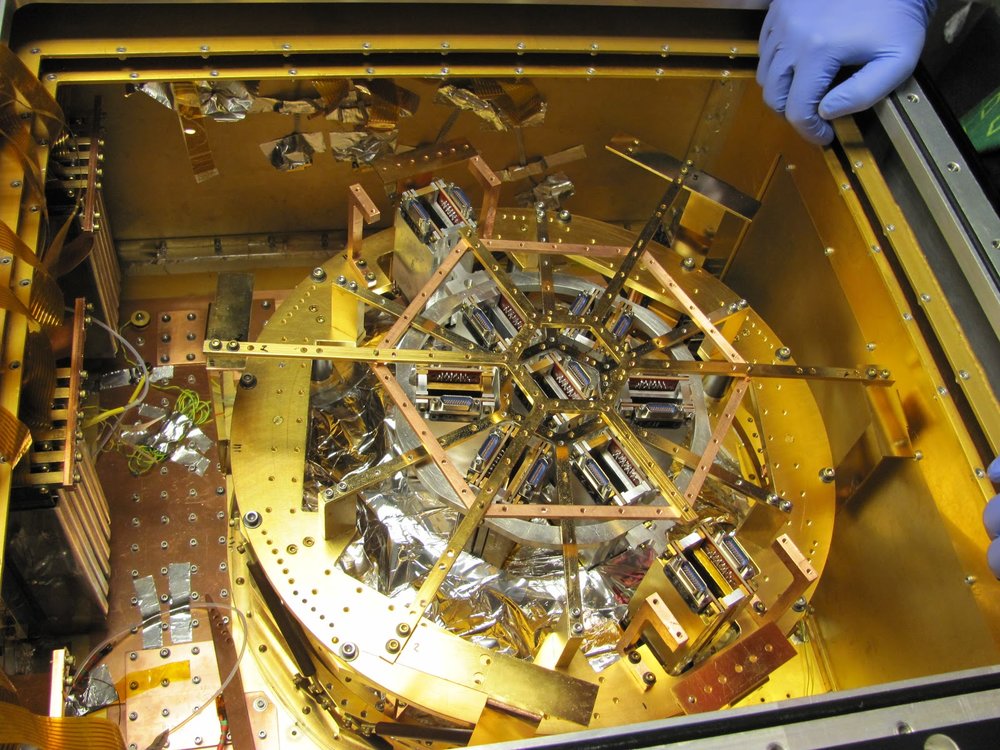

The camera back in Black Cat ready for us to hook up thermometry, heat sinking, and internal readout cabling. (Credit: AB)

A group photo after Black Cat was successfully mated to the secondary cryostat again. (Credit: AB)